Interlux VC17 Overcoating Recommendation

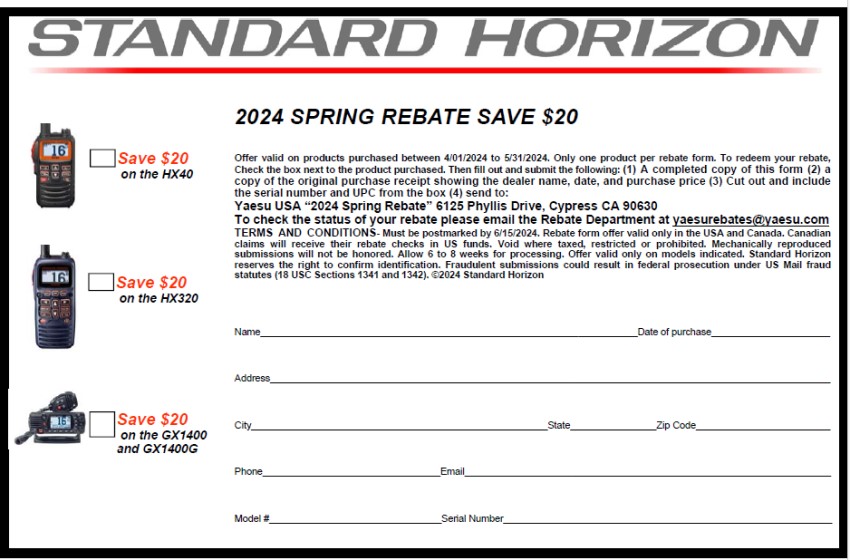

Current & Upcoming Consumer Rebates

We Have MOVED !!!

We are now located at 1452 Bath Road West Ramp Door, a short 7 minute drive East from our previous location. Our new location will offer enhanced customer browsing & parking, upgraded shipping/receiving facilities, and enough space to get all our inventory under one roof again! There is much work to be done to the "store" portion of the building, our goal is to be 95% done by March 1st, your patience during this transition is appreciated.

Spring Commissioning Checklist: Scroll to bottom of this page!

How to Measure Steering Cables

How do I paint my anodized aluminum mast?

It is difficult to paint over anodizing. If it is in very poor shape remove it before painting. To paint anodized first degrease using Fiberglass Solvent Wash 202. Then give it a heavy sanding using 60 or 80-grit sandpaper. Apply one coat of InterProtect 2000E (Thinned 15-20% with 2316N Reducing Solvent). Allow to dry overnight and apply a second coat of either Epoxy Primekote (thinned 25%) or Pre-Kote primer. Sand and apply Perfection (if using Epoxy Primekote) or Brightside (if using Pre-Kote).

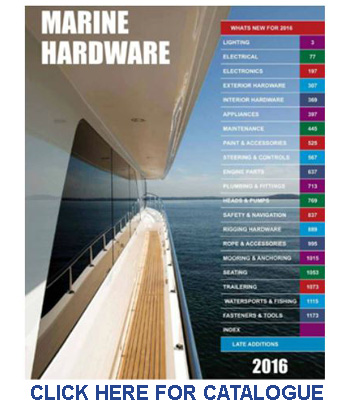

While we try to get as much product online as reasonably possible, if you can't find it on our site, you might find it in our Distributor's catalogue ! These companies are wholesalers and do not sell to the public, however, if you see something you like, we would be happy to get you pricing and availablity! You can download the catalogues by clicking the covers below:

|

|

|

|

|

|

Spring Commissioning Checklist compliments of BoatUS

Before You Launch

• Inspect and replace hose clamps as necessary. Double clamp fuel lines and exhaust hoses with marine-rated stainless-steel hose clamps. It’s a wise move to double clamp whenever possible on all hoses - especially those below the waterline.

• Inspect all hoses for stiffness, rot, leaks and cracking, and replace any that are faulty. Make sure they fit snugly.

• Inspect prop(s) for dings, pitting and distortion. Make sure cotter pins are secure.

• Grip the prop (on inboard drive systems) and try moving the shaft up and down and side to side. If it’s loose and can be wiggled, the cutless bearing may need to be replaced.

• Check the rudderstock to ensure it hasn’t been bent. Operate the wheel or tiller to ensure the steering works correctly.

• Inspect the hull for blisters, distortions and stress cracks.

• Make sure your engine intake sea strainer (if equipped) is not cracked or bent from ice and is free of corrosion, clean and properly secured.

• With inboards, check the engine shaft and rudder stuffing boxes for correct adjustment. A stuffing box should leak no more than two drops each minute when the prop shaft is turning.

• Inspect, lubricate and exercise seacocks.

• Use a garden hose to check for deck leaks at ports and hatches. Renew caulk or gaskets as necessary.

• Inspect and test the bilge pump and float switch to make sure they’re both working properly.

• Check stove and remote LPG tanks for loose fittings and leaking hoses.

• Inspect dock and anchor lines for chafe and wear.

• If equipped, ensure that the stern drain plug is installed.

• After the boat is launched, be sure to check all thru-hulls for leaks.

Engines and Fuel Systems

• For inboard engines, replace the water pump impeller, keep last years as a spare, toss the one from the year before.

• Add fuel treatment to gasoline / diesel tanks.

• Check engine oil levels & check gearbox fluid level..

• Check bilge for any evidence of fuel, oil or coolant.

• Check exhaust and air filter is clear - ensuring that no creatures have built nests, blockages.

• Check steering cables for condition and tension.

• Inspect fuel tanks, fuel pumps and filters for leaks. Ensure portable tanks and lines are completely drained of stale fuel before filling with fresh fuel. Clean or replace fuel filters and/or fuel-water separators if not done before winterization.

• Every few years, remove and inspect exhaust manifolds for corrosion (for inboard-powered and inboard/outboard boats).

• Charge battery.

• Clean and tighten electrical connections, especially both ends of battery cables. Use a wire brush to clean battery terminals, and top up cells with distilled water (if applicable).

• Inspect the bilge blower hose for leaks and run the blower to confirm correct operation.

Engine Outdrives and Outboards

• Inspect rubber outdrive bellows for cracked, dried and/or deteriorated spots (look especially in the folds) and replace if suspect.

• Check power steering and power trim oil levels.

• Replace anodes/zincs that are more than half wasted.

• Inspect the outer jacket of control cables. Cracks or swelling indicate corrosion and mean that the cable must be replaced.

• Inspect lower unit oil level and top up as necessary.

Sailboat Rigging

• Inspect swage fittings for cracks and heavy rust (some discoloration is acceptable). Inspect wire halyards and running backstays for “fishhooks” and rust.

• Remove tape on turnbuckles and lubricate threads, preferably with Teflon. Replace old tape with fresh tape but don’t wrap airtight.

• Prior to stepping the mast check lights and other electrical connections

• Check that spreaders, stays and shrouds are fit for service, if the standing rigging is over 15 years old, they are due for replacement.

• Following stepping the mast, tune the shrouds and stays to the proper tension and pin/lock all turnbuckles.

• If you suspect the core around a chainplate is damp, remove the chainplate to inspect and make repairs.

Trailers

• Inspect tire treads and sidewalls for cracks or lack of tread and replace as necessary. Check air pressure; don’t forget the spare.

• Inspect wheel bearings and repack as necessary.

• Test all lights and replace any broken bulbs or lenses.

• Inspect winch to make sure it’s working properly. Inspect hitch chains.

• Inspect trailer frame for rust. Sand and paint to prevent further deterioration.

• Inspect brakes and brake fluid reservoir.

Safety

• Check expiration dates on flares. Flares expire 4 years after the date of manufacture.

• Inspect fire extinguishers. Replace if more than 12 years old or if age is unknown. More than 40 million Kidde extinguishers with plastic handles were recalled on Nov. 2, 2017.

• Ensure you have properly sized and wearable life jackets in good condition for each passenger, including kids. Check inflatable life jacket cylinders and dissolvable “pill” bobbins in auto-inflating models.

• Test smoke, carbon monoxide, fume and bilge alarms.

• Check running lights for operation and spare bulb inventory.

• Update paper charts and chartplotter software.

• Replenish first-aid kit items that may have been used last season or are expired.

• Check the operation of VHF radio(s) and that the MMSI number is correctly programmed in.

For the Dock

• In addition to checking its entire length for wear or abrasions, check both ends of the shore power cable connections for burns, which indicate the cable and/or boat’s shore power inlet or the dock’s receptacle must be replaced.

• Test ground-fault protection on your boat and private dock, and know how to prevent Electric Shock Drowning.

The Paperwork

• Make sure your boat registration is up to date and a copy is on board.

• Review your boat insurance policy and update coverage if needed.